The building material “concrete” has the vastest utilization world wide. The performance of concrete have continuously rise in order to accomplish the society needs. This fact leads to obtaining an economic cost of product on short and long periods. Thus an innovative concrete “self compacting concrete” was found that does not require vibration for placing and compaction. SCC is an exciting new concrete technology.

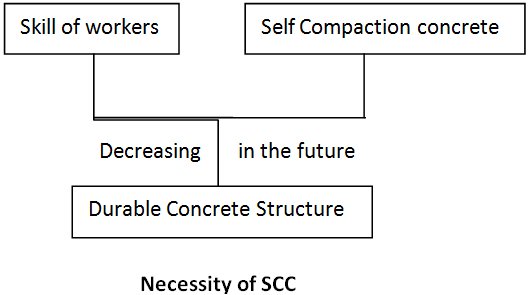

SCC was developed initially in Japan in 1980’s to offset the growing shortage of skilled labour. Self compaction concrete is a flowing concrete mixture that is able to consolidate under its own weight. Such concrete can be used for casting heavily reinforced sections, places where there can be no access to vibrators for compaction and in complex shapes of formwork which may otherwise be impossible to cast. SCC does not require vibrations, it achieve compaction into every part of the mould or formwork simply by means of its own weight without any segregation of the coarse aggregate. When large quantity of heavy reinforcement is to be placed in a reinforced concrete member it is difficult to ensure that the formwork gets completely filled with concrete, that is fully compacted without voids or honey combs. Compaction by manual or by mechanical vibrators is very difficult in this situation. This problem can be solved with self compacting concrete. This type of concrete flows easily around the reinforcement and into all the corners of the formwork. It is also called as self consolidating concrete or self leveling concrete.

The composition of SCC is in addition to cement and water, consists of high amount of super plasticizer and a viscosity modifying agent. Super Plasticizer can increase flowability without changing viscosity. Super plasticizers are a water reducing mixture that cause a significant increase in flowability with little effect in viscosity.For a mixture to have self compatibility it should have filling ability ,passing ability and segregation resistance. Slump test is used to find the filling ability of SCC. L Box test is used to find the passing ability of SCC. V funnel test is used to find the segregation resistance of SCC.

After committing various trial tests, we have finally achieved M30 grade self compacting concrete for different size of coarse aggregates. From the observations it was found that nearly half of the compression strength is gained in 3 days and 2/3 rd of strength in 7 days curing.

SCC must be highly workable than conventional concrete so that it can move under the force of gravity without vibration.

The new generator of poly carboxylate based super plasticizer has taken SCC a great step forward. Today we can speak of self compacting concrete which is transported by pumps to a height even up to 600 m, aout concrete which can be continually placed into congested reinforcement and which can be placed into forms under the action of self weight only, with out vibration. As a material it seeks new standards in production and control. A cost effective self compacting concrete design can be obtained by incorporating reasonable amount of Silica fume, fly ash and ground granulated blast funace slag.

SCC enables faster construction, reduction in site man power, better finish surface, easier placing, improved durability, reduced noise level and safer working environment. The improved construction practice and performance, combined with the health and safety benefits makes SCC a very attractive solution for both pre cast concrete and civil engineering.

By Geetha Padmakumar, Assistant Professor, Department of Civil Engineering, Trinity College of Engineering

Content retrieved from: https://thetrinitycollege.wordpress.com/2013/12/04/self-compacting-concrete/.