Seismic isolation is a good concept in earthquake engineering, having been introduced in the early 1980s in the USA and New Zealand, and as early as 1975 in the former Soviet Union. Quite simply, the idea underlying the technology is to detach the building from the ground in such a way that the earthquake motions are not transmitted up through the building, or are at least greatly reduced. Seismic isolation is most often installed at the base level of a building and is called base isolation. This new concept meets all the criteria for a classic modern technological innovation: the necessary imaginative advances in conceptual thinking, new materials available to the industry, and as can be seen in the WHE reports using isolators, simultaneous development of the ideas worldwide.

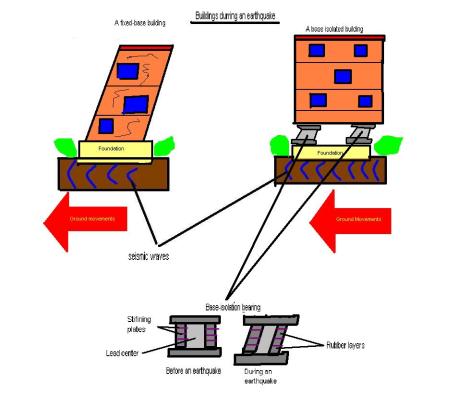

The principle of seismic isolation is to introduce flexibility at the base of a structure in the horizontal plane, while at the same time introducing damping elements to restrict the amplitude of the motion caused by the earthquake. The concept of seismic isolation became more feasible with the successful development of mechanical energy dissipators and elastomers with high damping properties. Seismic isolation can significantly reduce both floor accelerations and interstory drift and provide a viable economic solution to the difficult problem of reducing nonstructural earthquake damage.

There are three basic elements in any practical seismic isolation system. These are as follows:

• A flexible mounting so that the period of vibration of the total system is lengthened sufficiently to reduce the force response

• A damper or energy dissipator so that the relative deflections between building and ground can be controlled to a practical design level

• A means of providing rigidity under low (service) load levels, such as wind and minor earthquakes

Seismic isolation achieves a reduction in earthquake forces by lengthening the period of vibration in which the structure responds to the earthquake motions. The most significant benefits obtained from isolation are thus in structures for which the fundamental period of the building without isolation is short less than one second. Therefore, seismic isolation is most applicable for low-rise and medium-rise buildings and becomes less effective for high-rise structures.

The WHE reports describe the applications of two different isolation systems:

- • Rubber-based isolation system

- • Sliding-belt isolation system

The rubber-based isolation system has been widely used in China. The system consists of laminated rubber bearings, with a diameter of 350 mm to 600 mm and a thickness of 160 mm to 200 mm. The isolators are reinforced by thin steel sheets. The isolators are installed on top of the basement walls or the columns, or at the plinth level in buildings without a basement. The most common application in China is for those buildings where the superstructure consists of common multistory, brick-masonry walls with reinforced concrete floors/roof. The cost of this system is US$145/m2. By the end of 2003, the system had been used in over 460 residential buildings in China. Sliding-belt isolation systems are installed at the base of the building between the foundation and the superstructure. The sliding belt consists of the following elements: (a) sliding supports, including the 2-mm-thick stainless steel plates attached to the foundation and 4-mm Teflon (PTFE) plates attached to the superstructure, (b) reinforced rubber restraints for horizontal displacements (horizontal stop), and (c) restraints for vertical displacements (Uplift)–vertical stops. Once the earthquake base shear force exceeds the level of the friction force developed in the sliding belt, the building (superstructure) starts to slide relative to the foundation. A typical large-panel building with plan dimensions 39.6 m x 10.8 m has 63 sliding supports and 70 horizontal and vertical restraints. The sliding-belt scheme was developed in CNIISK, Kucherenko (Moscow) around 1975. The first design application in Kyrgyzstan was made in 1982. To date, the system has been applied in over 30 buildings in Bishkek, Kyrgyzstan. The applications include 9-story, large, concrete panel buildings and 3-story brick masonry wall buildings.

In the USA, New Zealand, Japan, and Italy, base-isolation technology has been used primarily to protect critical facilities, such as bridges, hospitals, city halls, courthouses, and heritage buildings. The most popular devices for seismic isolation of buildings in the USA are lead-rubber bearings, high-damping rubber bearings, and the friction pendulum system (FPS). In Japan, as of 1999, over 300 residential buildings were protected with base-isolation devices2 (note that there were 700 base-isolated buildings in Japan at that time). Typical residential buildings are reinforced concrete frame or wall construction, more than 5 stories, perhaps containing hundreds of apartments. The majority of baseisolated residential buildings in Japan were built after the 1995 Kobe earthquake (M7.3), which caused over 6,000 deaths, mainly as a result of vulnerable older wood housing.

Source: ADVANCED TECHNOLOGIES IN HOUSING CONSTRUCTION Farzad Naeim, John A. Martin Associates, USA. Svetlana Brzev, British Columbia Institute of Technology, Canada.

Content retrieved from: https://buildcivil.wordpress.com/2013/11/06/earth-quake-design-seismic-isolation/ .