The 5th International Conference of Euro Asia Civil Engineering Forum (EACEF-5)

Abstract

Steel has been used for many decades in structural applications because of its good combination of mechanical properties. As per recent concept to reduce steel consumption in reinforced cement concrete (RCC) structures, designers recommend high strength steel bars. There are various routes for their production such as microalloying, thermomechanical treatment, cold working, etc. For steel bars of thermomechanical treatment (TMT) route, some designers believe these steel bars to be more sensitive to corrosive environment. To verify this, corrosion behaviours of high strength steel bars of 500W (weldable steel bar of yield strength 500MPa) grade of two different local industries have been studied in fresh water and sea water, which were compared with weldable low strength (yield strength 300MPa) bars of the same companies. Experimental results revealed that addition of small amount of alloying elements such as Cr, Ni and Cu improves the corrosion resistance of the steel bars in all test mediums; however, strength levels have no influence the corrosion rate. A relation has also been found between the severity of corrosion damage and the degree of tensile property degradation.

©20155TheAuthors.Published.by byElsevierElsevierLtd.LtdThis. is an open access article under the CC BY-NC-ND license

(Peerhttp://creativecommons-reviewunderresponsibility.org/licenses/byoforganizing-nc-nd/4.0/committee). of The 5th International Conference of Euro Asia Civil Engineering

Peer-review under responsibility of organizing committee of The 5th International Conference of Euro Asia Civil Engineering Forum (EACEF-5).

Forum (EACEF-5)

Keywords: TMT Steels, Corrosion, Structural steel, Low alloy steel, RCC reinforcement.

- Introduction

Steel has been used for many decades in structural and engineering purposes both in land and marine environments because of its good combination of mechanical properties. The main problem of structural steel is its corrosion by various environmental species [1-4]. In general, concrete is reinforced by steel bars in the case of RCC structures. For

- Corresponding author. Tel.: 880-2-9665618; fax: 880-2-9665618, 8613046.

E-mail address: [email protected]

1877-7058 © 2015 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

Peer-review under responsibility of organizing committee of The 5th International Conference of Euro Asia Civil Engineering Forum (EACEF-5)

doi:10.1016/j.proeng.2015.11.084

624 Md. Aminul Islam / Procedia Engineering 125 (2015) 623 – 630

a long time, conventional hot rolled and normalized mild steel bars have been used for reinforcing concrete structures in Bangladesh. But, from few years back, this type of steel is being superseded by high strength one as it reduces the total steel consumptions [5-8]. In general, higher level of residual stress is thought to be responsible for higher corrosion rate [9-11]. At the same time, many authors mentioned that high strength TMT steel bars having minor residual stress at surface area do not show noticeable accelerated corrosion rate [12-16]. The aim of this work is to do detail research on the locally produced high strength steel bars in Bangladesh as this has not been done yet.

- Materials and Experimental Procedure

2.1. Materials preparation

The materials used in this experiment were locally produced steel bars (produced by conventional hot rolled and atmospherically cooled low strength 300MPa steel bars and TMT high strength 500MPa steel bars) of two different companies. Here it is to be mentioned that, in this paper, high strength steel bars will also be denoted by HS TMT Steel 1 or 2 (1 and 2 denote two different companies) and low strength conventionally hot rolled and atmospherically cooled bars will be denoted by LS HR Steel 1 or 2.

2.2. Chemical composition identification

The chemical compositions of the collected steel bars of two different companies were known by optical emission spectroscopy (OES: Shimadzu, Japan) and are presented in Table 1.

Table 1: Chemical compositions of the used steel bars.

| Steel ID | Fe | C | Si | Mn | S | P | Cu | Cr | |

| HS TMT steel | 98.2 | 0.16 | 0.12 | 0.68 | 0.02 | 0.04 | 0.50 | 0.20 | |

| 1 | |||||||||

| LS HR steel 1 | 98.2 | 0.16 | 0.12 | 0.68 | 0.02 | 0.04 | 0.50 | 0.20 | |

| HS TMT steel | 98.9 | 0.13 | 0.11 | 0.56 | 0.03 | 0.03 | 0.10 | 0.06 | |

| 2 | |||||||||

| LS HR steel 2 | 98.9 | 0.13 | 0.11 | 0.56 | 0.03 | 0.03 | 0.10 | 0.06 |

2.3. Metallography

Metallographic samples were also cut and prepared for observation under metallurgical microscope following standard procedure. After complete polishing, the faces of each sample of all HS and LS steel grades were etched in 2% Nital solution.

2.4. Corrosion test

For corrosion tests, simple immersion mass loss process for determining the corrosion rates has been used. The corrosion rates of different types of steel bars of each company in various test media (fresh water and sea water) have been compared. Here it is to be mentioned that for corrosion tests steel bars were used in the as received conditions and for all cases, corrosion tests were continued for 56 days. However, after every 7 days (one week) of immersion, test samples were taken out of the solution, washed in water to clean the rusts accumulated on the steel bar surfaces and they were then completely dried. After that the mass losses were measured using a very sensitive digital balance. This experimental cycle has been repeated for 56 days, i.e. for each sample, weight losses were measured for eight times.

2.5. Tensile test

Tensile tests were carried out for all steel bars before and after corrosion tests using a tensile testing machine (Shimadzu, Japan) of capacity 500kN. The effects of corrosion on tensile properties were observed by this experiment.

| Md. Aminul Islam / Procedia Engineering 125 (2015) 623 – 630 | 625 |

- Results and Discussion

The chemical compositions of the HS TMT steel bars and conventional LS HR steel bars are presented in Table

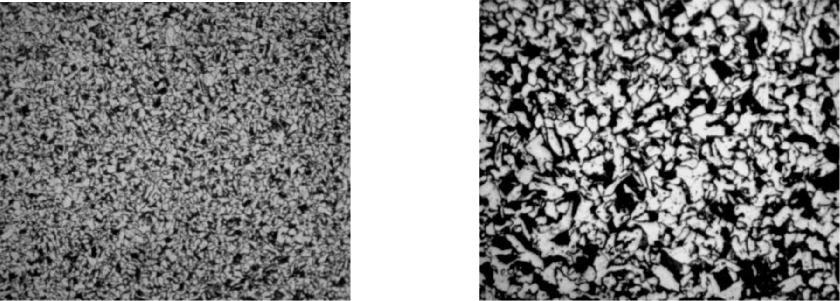

- As per this table the chemical compositions of steel bars supplied by two local companies are not the same. Steel bars collected from company 1 (HS TMT and LS HR steels 1) have slightly higher carbon content, but their manganese, chromium and copper contents are significantly higher than that of steel bars collected from company 2 (HS TMT and LS HR steels 2). Both companies produce steel bars maintaining almost similar production process parameters, however, they showed different corrosion rates because of different chemical compositions and resulted final microstructures. The macrographs of the polished bars, after etching of the polished specimens in 2% Nital, are presented in Fig. 1 and Fig. 2.

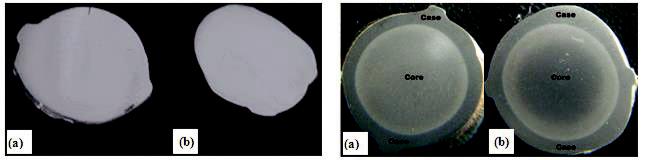

| Fig. 1. Macrographs showing the case free section areas of | Fig. 2. Macrographs showing the section areas with case and |

| low strength bars (a) steel 1 and (b) steel 2. | core of high strength bars (a) steel 1 and (b) steel 2. |

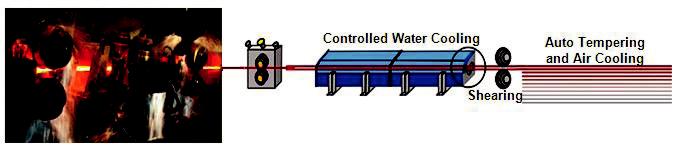

Due to etching effects, for both the companies, the peripheral cases and cores of HS TMT steel bars were revealed very clearly. This is mainly due to the production technology. During the production of this type of steel bar, after final hot rolling, the red heated steel bars are passed through a chamber with controlled water flow (Fig. 3) that quenches the surface and sub-surface areas of the bars very quickly where martensite is formed. However, the core temperature remains very high, Fig. 4.

Fig. 3. Production steps for high strength TMT steel bars.

626 Md. Aminul Islam / Procedia Engineering 125 (2015) 623 – 630

Water

Quenched

Cold Zone  High

High

Temperature

Inner Core

Fig. 4. Cross section of HS TMT bar just after controlled water quenching

(a) (b)

(a) (b)

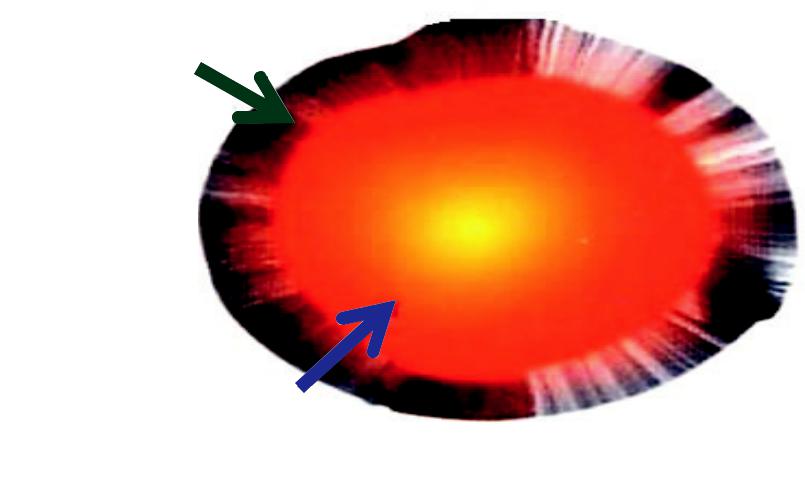

Fig. 5. Microstructures of case areas of high strength TMT steel bars (a) steel 1 and (b) steel 2.

When steel bars are finally cooled in atmospheric air on the cooling bed, heat from the core comes out and tempers the previously formed martensite in the outer surface and sub-surface areas. Because of tempering, residual stress of outer quenched martensite layer gets released. At the same time, normalizing action during air cooling results ferrite-

pearlite microstructures in the core areas. As a result, tempered martensite and normal ferrite-pearlite microstructures are formed, respectively, at the outer surface and core areas of the HS TMT steel bars. Because of these dissimilar microstructures, during etching, total surface areas responded differently during etching. So, for TMT steel bars, cases (darker portion) at the outer areas are observed, Fig. 2. On the other hand, conventional LS HR steel bars are fully cooled in the atmosphere, where uniform ferrite-pearlite microstructures are formed. These ferrite-pearlite microstructures over the whole cross sectional area are responsible for uniform etched surface for these steel bars, Fig. 1.

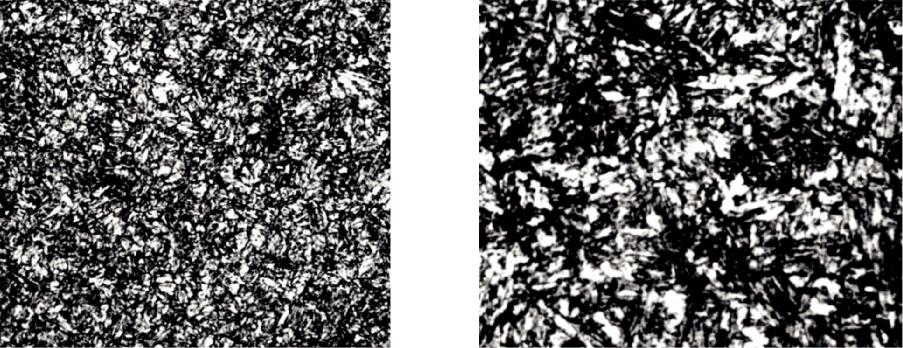

At low magnification (macrostructures), the internal microstructural features (various phases, grain sizes, their shapes, orientations, volume fractions, etc) are not possible to reveal and this was made possible by microstudy. After detailed microstudy of all etched steel bars, they were photographed, which are presented in Figs. 5-6. From Fig. 5, it is clear that surface microstructures of HS TMT steel 1 are finer than that of steel 2. Similar to HS TMT steel 1, conventional LS HR steel 1 also showed finer grain size than that of LS HR steel 2, Fig. 6. Alloying elements like manganese, chromium, nickel, vanadium, copper, etc refine the ferrite-pearlite grains of steels, which has been established by many researchers [17-19]. These alloying elements also restrict the growth of austenite at high temperature. As steel 2 contains these elements in lower amount, so austenite grain size of this steel was larger, which ultimately resulted coarser tempered martensite as well as ferrite-pearlite in its microstructures, Figs. 5 and 6.

| Md. Aminul Islam / Procedia Engineering 125 (2015) 623 – 630 | 627 |

(a) (b)

(a) (b)

Fig. 6. Microstructures of both case and core areas of low strength HR steel bars (a) steel 1 and (b) steel 2.

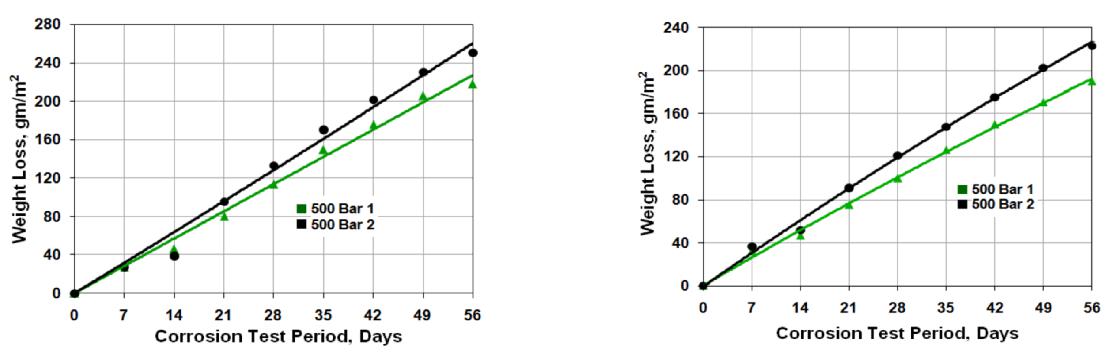

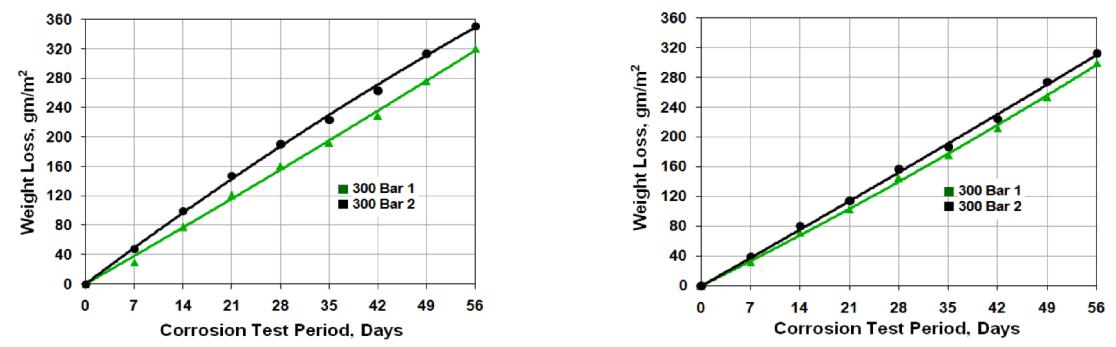

The graphical representations of the corrosion behaviours of these two different steels, both in HS and LS conditions, in various mediums are shown in Figs. 7-10, where the abscissa represents the number of days for how long test samples were immersed in corrosion medium and the ordinate expresses the cumulative weight loss per unit surface area of steel bars.

Fig. 7. Corrosion rates of HS TMT bars in water Fig. 8. Corrosion rates of HS TMT bars in sea water.

Fig. 7. Corrosion rates of HS TMT bars in water Fig. 8. Corrosion rates of HS TMT bars in sea water.

Fig. 9. Corrosion rates of LS conventional steel bars in water. Fig. 10. Corrosion rates of LS conventional steel bars in sea water

Fig. 9. Corrosion rates of LS conventional steel bars in water. Fig. 10. Corrosion rates of LS conventional steel bars in sea water

From Figs. 7-10, it is clear that sea water caused higher corrosion rate for all steel bars. Many investigators mentioned chloride ion to be a very powerful agent for corrosion of iron based alloys [20-22]. In the case of sea water the higher corrosion rate was arguably due to the availability of chloride ions in it. Concerning corrosion rate, the most important observation is that high strength steel bars for both groups (steel bars of groups 1 and 2) corroded in a significantly slower rates than that of the corresponding low strength conventional steel bars. Some practicing designers show reluctant in using HS TMT steel bars as they believe these steel bars to be more corrosion sensitive in RCC structures. From this study, it has been clearly revealed that high strength is not the only parameter to control the corrosion sensitivity of steel bars. There are many other important parameters; the grain size of the steel bars as well as alloying elements that also influence the corrosion rate significantly. From Figs. 5 and 6, it is very clear that the surface microstructures of TMT steel bars are significantly finer than that of the corresponding LS HR grade steel

628 Md. Aminul Islam / Procedia Engineering 125 (2015) 623 – 630

bars. Rifai et al showed that corrosion potential is more sensitive to grain size than strength [23]. There is no doubt that residual stress in steel causes accelerated corrosion. At the same time, finer grains also ensure lower corrosion rate. So, arguably there is competition between residual stress, which tends to increase the corrosion rate and finer grain sizes that tend to decrease the corrosion rate. In the case of HS TMT steel bars, residual stress gets released during auto tempering. The observed corrosion results suggest an increase in corrosion rate due to residual stress (if there is any) is not sufficient to overcome the reduced corrosion rate caused by the refined grains. For HS TMT steel bar production, a high technology is used that ensures minimum residual stress at the hardened surface areas. Earlier investigations [11,23] confirmed the importance of technological process of manufacturing and processing of reinforcing bar on properties of high strength bars. They established that HS steel bars produced in cold working route contains a very high level of residual stress (macro stress) that have a substantial impact on corrosion behaviour of reinforcing bar in the concrete.

Similar to grain size, there is another important effect of alloying elements on the corrosion rates of steel bars. From Figs. 7-10 we can see, for both the high strength and low strength grades, the corrosion rates of steel 1 are lower than that of the corresponding grade of steel 2. As per Table 1, steel bars of group 1 have higher levels of chromium and copper contents, which are very effective to reduce the corrosion rate. As a result, in all corrosion test mediums, both grades of bars (500 grade i.e. HS TMT bars or 300 grade i.e. LS HR bars) of steel 1, showed lower corrosion rates. Considering all, it is arguable to suggest that, in the case of sea coast or heavily industrial areas, it is wise not to use plain carbon steel bars, whether they are conventional low strength grades or high strength TMT grades to avoid severe corrosion related damages to the RCC structures and to achieve longer service life of the structures. Although, it is thought by some users as well as designers that the corrosion rates of high strength TMT bars are higher than the low strength conventional steel bars of similar chemical compositions, no such evidence has been found in this research. So, TMT steel bars containing sufficient amount of corrosion reducing alloying elements such as copper, chromium and nickel are more suitable for uses in the coastal as well as industrial areas.

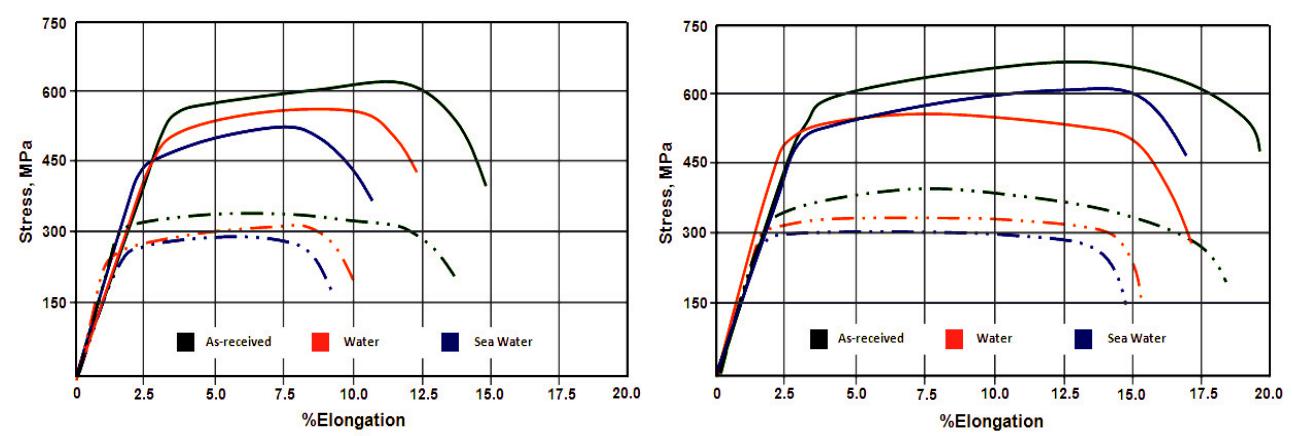

Tensile tests of two types of steels, both in high and low strength conditions, before and after corrosion tests in two different mediums were performed using universal testing machine. The graphical representation of tensile behaviours for each steel bar and the effects of corrosion on tensile properties have been shown in Figs. 11 and 12. Here, Figs. 11 and 12, respectively, refer to the stress-strain graph of steels of groups 1 and 2. If we consider the effect of corrosion on strength and elongation, it is clearly observed that corrosion caused a reduction in the strength and elongation for steel bars of low and high strength levels for both groups of steel bars. Now, if we consider the effects of corrosion test media, the corrosion in sea water has been found to be more damaging than that of just fresh water for tensile properties of both groups of steel bars of all strength levels (Figs. 11 and 12).

| Fig. 11. Tensile behaviours of low (dotted lines) and high strength | Fig. 12. Tensile behaviours of low (dotted lines) and high strength |

| (solid lines) steel bars of group 2 | (solid lines) steel bars of group 2 |

The elongations have also been reduced after corrosion tests both in fresh and sea water. Alloying elements reduced the corrosion rates of steels of group 1. This means pits formed on bars of group 1 were shallower and deeper for steel bars of group 2.

| Md. Aminul Islam / Procedia Engineering 125 (2015) 623 – 630 | 629 |

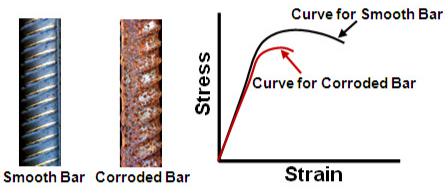

Fig. 13. Smooth bar, corroded bar and schematic diagram showing the tensile behaviours of these bars

Fig. 13. Smooth bar, corroded bar and schematic diagram showing the tensile behaviours of these bars

Finally, these pits on corroded bars cause stress concentration under loading condition and change the tensile behaviours of the steel bars, which is shown schematically in Fig.13. Deeper pits mean higher stress concentration and more possibility of premature failure. As a result, bars with deeper pits lose their ultimate tensile strength, yield strength and elongation relatively to higher extents.

- Conclusions

Although, it is thought by many users as well as designers that the corrosion rate of high strength thermomechanically treated (TMT) steel bars are much higher than that of low strength conventional hot rolled (HR) steel bars of similar chemical compositions, no such evidence has been found in this research work. Finer tempered martensites or ferrite-pearlite grain sizes and presence of small amount of alloying elements rather, than the strength levels of the steel bars, have been found to be more effective to reduce the corrosion rates either in normal water or sea water medium. So, TMT steel bars containing sufficient amount of corrosion reducing as well as grain refining alloying elements such as copper, chromium and nickel are more suitable for uses in the coastal as well as industrial areas where corrosion of steel bars in RCC is a great concern.

Acknowledgement

The author would like to express his gratitude to CASR as well as BUET authority for providing him the necessary fund and to use laboratory facilities to conduct this research work.

References

- F. Perenchio, Corrosion of Reinforcing Steel, ASTM STP 169C, (1994) 164-172.

- S. Berke, Corrosion Inhibitors in Concrete, Concrete International, 13 7(1991) 24-27.

- Report on Materials and Methods for Corrosion Control of Reinforcement and Prestressed Concrete Structures in New Construction, Publication Number 00-081, (2000), US Department of Transportation, Federal Highway Administration.

- Etmanc, Reinforced Concrete Corrosion and Protection, Concrete Research Letter, 3 1(2012) 359-372.

- S. Bari, Use of 500 Grade Steel in the Design of Reinforced Concrete Slab, http://www.bsrm.com/resources/Dr.S.Bari_BSRM_Paper_on_Slab.pdf

- Bob, H. Scott, High-Strength Reinforcing Steel: Next Generation or Niche?, Concrete Construction Magazine, January, (2008).

- Plain and Reinforced Concrete, Indian Standard – Code Of Practice, (Fourth Revision), IS 456 (2000).

- S.Z. Bosunia, Design of Reinforced Concrete Structures and the Use of Various Grades of Steel, https://docs.google.com/file/d/0B9Klr-bgHz5XRWtXckNHUkpDb3c/edit?pli=1

- F. Bernezhnitskaya, Influence of Residual Stress on the Resistance of Steel to Corrosion-Mechanical Failure, Soviet materials science, a transl. of Fiziko-khimicheskaya mekhanika materialov/Academy of Sciences of the Ukrainian SSR, 23 1(1987) 19-23.

- P. Zhuk, Theory of Corrosion and Protection of Metals, Moscow Metallurgiya, (1976) 472-479.

- Yu. Ambrazhey, E. E. Chigirinets, G. Yu. Galchenko, A.V. Ivchenko, Effect of Technology Factors on Corrosion Resistance of Cold-Rolled Reinforcing Bar, Metallurgical and Mining Industry, 2 4 (2010) 302-308.

- Report on Corrosion Resistant TMT Steel Bars; http://priyankironsteel.com/electro_crs.pdf

- N. Mohanty, G. Jha, Corrosion Control Through Surface Modification, R&D, TATA STEEL: http://eprints.nmlindia.org/4100/1/O_N_Mohanty-1.PDF

- Manoharan, P. Jayabalan, K. Palanisamy, Experimental Study on Corrosion Resistance of TMT Bar in Concrete, International Conference

630 Md. Aminul Islam / Procedia Engineering 125 (2015) 623 – 630

on Construction and Building Technology (ICCBT), (2008) 239-250.

- K. Panigrahi, S. Srikanth, G. Sahoo, Effect of Alloying Elements on Tensile Properties, Microstructure and Corrosion Resistance of Reinforcing Bar Steel, J. Mat. Engg. Perform, ASM International, 18(2009) 1102-1108.

- Report on TMT Rebars, Dedicated to Build a Strong Nation, 2014: http://www.thebig5constructindia.com/media/191965/TMT-Rebars_-dedicated-to-build-a-strong-nation.pdf

- A. Razzak, Heat Treatment and Effects of Cr and Ni in Low Alloy Steels, Bull. Mater. Sci., 34 7(2011) 1439–1445.

- Wang, M. Wang, J. Shi, W. Hui, Effect of Microstructure Refinement on Strength and Toughness of Low Alloy, J. Mat. Sci. Tech.., 23 5(2007) 659-664.

- Radović, A. Koprivica, D. Glišić, A. Fadel1, D. Drobnjak, “Influence of Cr, Mn And Mo On Structure and Properties of V Microalloyed Medium Carbon Forging Steels, Association of Metallurgical Engineers of Serbia (AMES), 16 1(2010) 1-9.

- U. Mohammed, H. Hamada, T. Yamaji, Performance of Seawater-mixed Concrete in the Tidal Environment, J. Cement and Concrete Res., 34(2004) 593-601.

- T. Ngala, C.L. Page, L.J. Parrott, S.W. Yu, Diffusion in Cementitious Materials: Further Investigations of Chloride and Oxygen Diffusion in Well-Cured OPC and OPC/30% PFA Pastes, Journal of Cement and Concrete Research, 24(1995) 819-826.

- Shin-ichi Miyazato1, Nobuaki Otsuki2, Steel Corrosion Induced by Chloride or Carbonation in Mortar with Bending Cracks or Joints, Journal of Advanced Concrete Technology, 8 2(2010) 135-144.

- Rifai, H. Miyamoto, H. Fujiwara, Effects of Strain Energy and Grain Size on Corrosion Resistance of Ultrafine Grained Fe-20%Cr Steels with Extremely Low C and N, International Journal of Corrosion, 2015(2015) 1-9.